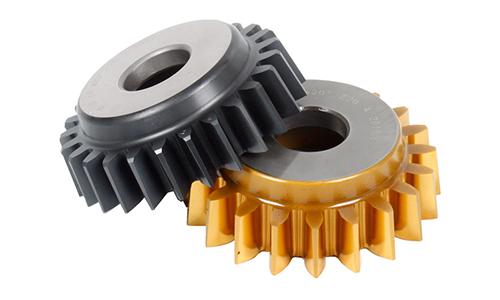

Gear shaping is an important method in gear construction. Gear is an essential asset in many machines. Creating gear is vital for smooth operation. With the gear shaper cutters manufacturers, you can get quality shapers for gear shaping. Utilizing the ideal shaping method is better to create gear. It requires a shaper cutter to cut teeth into a perfect piece of metal.

The cutter can rotate and reciprocate to make teeth. Cutting can happen at the upstroke or downstroke of the machine. During the manufacturing process, cutter axes and gear must be parallel with the cutter rotating in motion. Gear blank and cuter can go at the same velocity and train gear by generating motion between gear blank shaft and cutter.

When it is required:

Gear shaping is a reliable and simple method to make stunning gear. On the other hand, such a method is also efficient for gear cutting. The method is beneficial to develop external and internal gear and integral gear pinion arrangement.

Gear shaping is the best way to develop gear that resides very close to the flange and other surfaces in the desired machine. A shaper cutter is available with impressive accuracy for gear shaping. It is vital method for producing gear with low requirements for kinematic accuracy. It never requires grinding or shaving.

Produce quality and more quantity gear:

A shaper cutter is an essential tool for producing gear and attaining the perfect kind of gear formation. It is available in different forms like helical, harp, shank, and disc. Great utilization of a shaper cutter in the entire process will aid in boosting effectiveness and efficiency.

A shaper cutter is the best part of making gear in large quantity. The main reason for using a shaper cutter is that it delivers excellent quality gear that doesn’t compromise on different procedures. Rather than other processes, it has the great capability to produce a large number of gears within a short time. It is suitable for mass production of large and medium-sized gear.

Boost abrasion resistance:

Abrasion resistance can be decided based on the type of coating mechanism used in the shaper cutter. Every mechanism has a great effect on the surface. Shaper cutter can manufacture with coating options like TiCN, TiAIN, and TiN technologies. Each enhances resistance to a specific level and develops the surface range or material it cuts. The technician chooses the best coating option based on the work environment.

Perform in different environments:

A gear shaper cutter is the best component for professionals to make gear products easily. If you need a quality shaper, you can approach well-known gear shaper cutter manufacturers in india and get a shaper. It works in diverse environments where there is a lot of resistance.

Manufacturers use quality materials to build shaper. Material can source from the right smelter that tests and purifies to transport efficient cutter. Shaper has a stunning ability to withstand high temperatures, excess heat, and extreme friction. Cutter shaper performs a wonderful job and helps technicians manage the overall cost of maintenance.